EVOLVING AN INDUSTRY THROUGH REVOLUTIONARY MANUFACTURING & GLOBAL LICENSING

True Velocity's culture of innovation is responsible for the creation of manufacturing technology and process controls that have enabled the company to reimagine the design, production, and distribution of ammunition. Our state-of-the-art production lines are the result of countless hours of innovation and engineering from the brightest minds within multiple industries. Rather than finding ways to improve today's ammunition, we recruited industry experts in robotics, electrical engineering, polymer science, and molding to design the ammunition of the future. We apply best practices from the aerospace, pharmaceutical, and automotive industries to free our ammunition from the constraints of brass. These attributes in conjunction with our vast intellectual property portfolio, will facilitate a global licensing model, allowing for the distribution of our manufacturing technology to strategic locations both inside the United States and around the world.

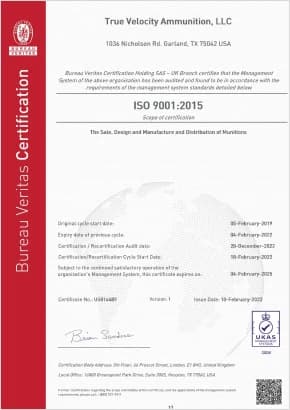

unbeatable quality control process

At True Velocity, our commitment to quality control is unwavering. We adhere to rigorous processes to ensure that every round of ammunition meets the highest standards of reliability and performance. From the sourcing of raw materials to the final product, our quality control process is comprehensive and thorough. We conduct extensive testing and inspections at various stages, including dimensional checks, functional testing, and ballistic performance evaluations. Our system-wide processes are designed to yield high-quality, precise parts without exception, requiring in-line, automated inspection and validation of every part we produce.

*ISO Registered ISO 9001:2015 REV. D

Partner with us

For inquiries related to manufacturing sales, please contact us.